Properties

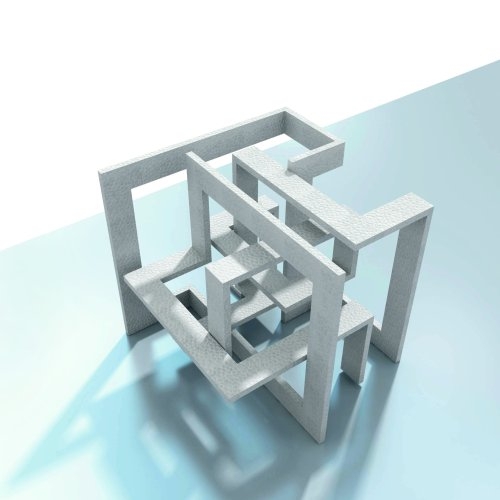

SHAPE MOULDING

EPERAN™-PP and EPERAN™ can be easily molded into complex shapes, accommodating a multitude of possible designs, using established steam chest molding techniques.

MULTI-IMPACT

When subjected to shock or vibration in transit, EPERAN™-PP and EPERAN™ can easily absorb stress and will not break or get deformed in normal use.

ENERGY ABSORPTION

EPERAN™-PP and EPERAN™ have outstanding cushioning and energy absorption properties and can, therefore, offer excellent solutions in the field of safety and protection for the automotive and other industries.

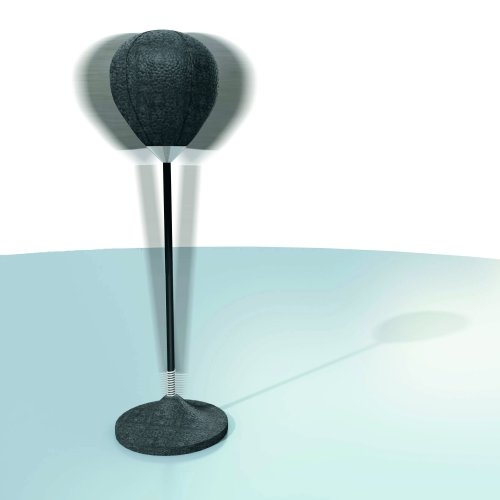

FLEXIBILITY AND RESILIENCE

EPERAN™-PP and EPERAN™ demonstrate outstanding elasticity and strain recovery properties, allowing the foam parts to return to their original shape even after severe bending or compression.

STRUCTURAL STRENGTH

EPERAN™-PP and EPERAN™ have high load characteristics and strength, high-temperature resistance and excellent creep characteristics – even at low densities.

DURABILITY

EPERAN™-PP and EPERAN™ have excellent impact strength, strain recovery and flexibility. Furthermore they have superior resistance to UV radiation, abrasion and other physical and environmental wear and tear.

LIGHTWEIGHT

Due to their outstanding cushioning properties, EPERAN™-PP and EPERAN™ can provide exceptional results with a minimum of volume and weight, thereby offering a more cost-effective solution in terms of transport, storage and overall weight reduction.

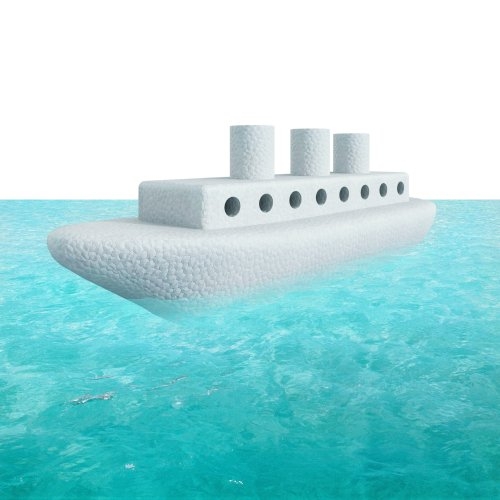

BUOYANCY

Thanks to the closed-cell structure, EPERAN™-PP and EPERAN™ have a superior long-term floatation capability, and they are not affected by lengthy exposure to either fresh or salt water.

THERMAL PROPERTIES

Being closed-cell foams, EPERAN™-PP and EPERAN™ have effective insulation properties and thermo-stability. In specially developed products, thermal insulation properties can reach an even higher level.

FLAME RETARDANCY

Although the flame retardant properties of standard EPERAN™-PP and EPERAN™ are limited, the non-halogen flame retardant grades dispose of self-extinguishing properties in both horizontal and vertical burning conditions. And in case of a fire, the heat release rate is low and the generated smoke is non-toxic.

CHEMICAL RESISTANCE

EPERAN™-PP and EPERAN™ show little or even no degradation when exposed to various oils and chemicals and have excellent weather and moisture resistance.

MULTI-GRADE MOULDING

Kaneka has developed a very cost-effective patented technology allowing the moulding of multiple grades in one and the same part, in order to meet specific requirements for the automotive and returnable container businesses.

VX-SECONDARY EXPANSION GRADES

The need to reduce transportation and logistics costs and to optimize density control have led Kaneka to develop Eperan™-PP grades especially suited for secondary expansion. They can be expanded more than 3 times in 1 step.

RECYCLABILITY

EPERAN™-PP and EPERAN™ consist of easily recyclable polypropylene and polyethylene.