Acrylic Binders for Plastisols

WHAT ARE ACRYLIC BINDERS FOR PLASTISOLS?

Kane Ace™ acrylic binders are used to produce halogen-free plastisols that feature a variety of advantages.

Benefits

-

Low gelling temperatures

-

Halogen-free formulations

-

Thermal stability

-

UV Resistance

-

Environmental friendly through clean incineration

-

Excellent sound insulating properties

-

Lightweight construction through good foaming behavior

-

Outstanding storage stability

Typical applications

-

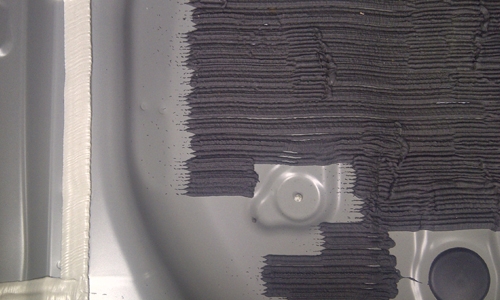

Automotive industry: underbody coatings, sealants and acoustic dampers

-

Textile coating, screen printing

-

Flooring applications

-

Structured wallpapers

-

Coil coatings

BINDERS FOR ACRYLIC UNDER BODY COATING (UBC)

Kane Ace™ UC506

Binder for acrylic under body coating (UBC) plastisols and sealing compounds.

Kane Ace™ UC508

Binder for acrylic under body coating (UBC) plastisols and sealing compounds with improved foaming behavior.

BINDERS FOR ACRYLIC ACOUSTIC DAMPERS

BINDERS FOR SOFT AND FLEXIBLE COATINGS

Kane Ace™ 4899F

Soft and flexible coatings for fabrics and paper substrates, silk - screen printing surfaces.

BINDERS FOR HARD AND TOUGH COATINGS

Kane Ace™ 4944F

Hard and tough coatings for metal, paper and fabrics especially on E-coated plastisols.

Kane Ace™ M914

Hard and tough coatings for metal, paper and fabrics, e.g. wall coverings.

BINDERS WITH BROAD PLASTICIZER COMPATIBILITY

Kane Ace™ BM310

Binder with broad plasticizer compatibility and low viscosity for e.g. coatings on paper and woven fabrics.